-40%

Blue Lightning Aluminum / Zinc Flexible Anode Rods, Hex Plug, 42"

$ 15.83

- Description

- Size Guide

Description

Prolong Your Water Heater LifeAnode Rods and Why You Need Them

Anode Rods and Cathodic Protection

Anode Rods, Cathodic Protection and the Porcelain (glass) Lining

Corrosion can be defined as the destructive attack of a metal by an electrochemical reaction with its environment. Steel exposed to moisture and oxygen will rust and corrode. Corrosion is defined as the "eating away" of metal by electrochemical means. There are four main factors affecting waters ability to corrode:

Acidity - Water is made acidic by naturally occurring dissolved gases such as carbon dioxide.

Temperature - Higher temperatures speeds up the corrosive process.

Amount of dissolved oxygen - Free oxygen dissolved in the water promotes corrosion.

Electrical conductivity - The more dissolved mineral solids in the water, the greater its ability to carry electrical current. When dissimilar metals are in the water:

Electrical current flows between metals

One of the metals gradually corrodes faster than the other

Dissimilar metals are present in the interior steel tank surfaces of all water heaters in several forms such as the drain nipples, heating elements, inlet and outlet nipples, and immersion thermostats. These metals, and others present in the water itself, combined with the oxygen content of the water and heat, establish an environment conducive to corrosion. The dissimilar metals create a corrosion cell that is enhanced by the conductivity of the water. The anode is installed to overcome (neutralize) the corrosive cell.

The Porcelain (glass) Lining

The Porcelain (glass) Lining

In a water heater, corrosion is protected by a glass (actually a porcelain enamel) lining in the steel tank, and the use of auxiliary anode rods. Porcelain enamel begins as a blend of minerals mixed in a manner to form liquid slurry. This slurry, resembling a thin mud, is sprayed onto the inner surfaces of the water heaters. During the manufacturing process, the inside water tank and both the top and bottom heads are sprayed with a slurry of glass material. After the tanks are sprayed, they are fired at very high temperatures - generally ranging from 1500 to 1600 degrees Fahrenheit. While in the furnace the porcelain bonds with the metal to create more than a coating. It forms an inseparable compound merging the chemical make-up of the porcelain glass lining and metal resulting in a new, chemically unique finish.

This glass provides a long life to the steel tank; otherwise, the tank would fail or corrode in a relatively short time. Every glass lined water tank, no matter how carefully it is manufactured, has some microscopic bare metal areas exposed to the water inside the tank. There is a chance that a crack or chip in the porcelain lining will allow the water to come in contact with the steel tank. Over time, water, a universal solvent that becomes more aggressive with temperature, slowly dissolves the interior tank lining. This will create conditions for corrosion, pinholes in the tank and finally tank failure.

(Microscopic view of steel and porcelain lining after firing)

Cathodic Protection

Cathodic Protection

(Life Cycle of an Anode Rod)

Cathodic protection is accomplished in the glass lined water heater by using an auxiliary magnesium anode. Due to the relative position of magnesium to steel in the electromotive series of metals, magnesium will corrode, producing an abundance of electrons which flow (much the same an electrical current) to the exposed steel surface and maintaining it in the electro-negative state. As current flow takes place, the anode rod reacts chemically to corrode at a rate faster than the steel inner tank. This process stops tank corrosion by substituting the sacrificial magnesium anode rod in place of the steel tank. As long as the magnesium anode rod remains in the tank, in an active state, there will be no corrosion of the minute areas of exposed steel inside the tank.

Anode Rods

Anode Rods

(Fully Depleted Anode Rod)

(Depleted anode rod)

The life of the anode, in turn, depends on water temperature, amount of water used, and the quality of the glass lining. However, the most important factor in the life of the anode rod is the water chemistry, the hardness or softness of the water. Water softeners contribute to the change in water chemistry. Indirectly, softened water acts to reduce the service life of the anode, since its current demand becomes drastically higher. Also, check the manufacture and installation date of the water heater.

Do not remove the anode rod from the water heaters tank, except for inspection and/or replacement, as operation with the anode rod removed will greatly shorten the life of the glass lined tank and will exclude warranty coverage. The anode rod should be removed from the water heaters tank annually for inspection and replaced when more than 6 inch of core wire is exposed at either end of the rod.

Which Anode Rod You Need

Magnesium Anode Rods and Smelly Water

Magnesium Anode Rods and Smelly Water

From time to time, questions are raised as to the use of magnesium anode rods. Generally, these questions are raised in areas where some unusual water problems occur with resultant odors. For many years, the regular magnesium anode was and is the standard anode for use in water heaters tanks. In general, it is a very good anode; however, the performance is dependent on water chemistry. In waters where the conductivity is low, the anode operates at a very low current level. This means not much cathodic protection. Conversely, where the water conductivity is high, an excessive amount of current is produced with inefficient operation. This will sacrifice the anode sooner than predicted and require more frequent replacement.

In addition, some of these waters have excessive sulfate content along with various strains of sulfate reducing bacteria (see Document 1206). These bacteria, harmless to health, will grow in the presence of the highly active magnesium anode rod and using the hydrogen ion from the anode-cathode reaction, will produce hydrogen sulfide gas. The gas smells like rotten eggs. The greater the activity of the anode, the more hydrogen ions are produced and the more hydrogen sulfide (smelly) gas. These bacteria can be killed with adequate additions of chlorine, such as with an automatic chlorine feeder.

When to Consider Aluminum

When to Consider Aluminum

Magnesium is the most widely used and in most cases the best alloy to use for water heater anode rods. However, on a rare occasion aluminum anode rods maybe the most reliable substitute.

If the following conditions apply to you then you are better suited for aluminum rods:

You use a well as your water source

You plan on going extended periods of time without using your water heater.

You have already experienced odor coming from your water heater

If you use a water softener it will speed up the deterioration of your anode rod regardless of what it is made of because it increases the salt levels in your water making it more conductive. You should check your anode rod every six months instead of once a year when using a water softener. Starting with a magnesium rod may be best if you can remember to check its condition twice a year. If you notice an odor replace with an aluminum rod as soon as detected. You can also add peroxide and temporarily increase the heat inside of the tank to kill the odor in most cases.

Warning:

Always run cold water through your pipes to flush any potential aluminum by-products from your water supply if you plan on ingesting the water.

Zinc to The Rescue!

Zinc to The Rescue

The Blue Lightning Magnesium Flexible Anode Rod uses a signature alloy that has a small amount of zinc in it to combat potentially smelly bacteria. In conditions that do not involve the ones mentioned on the previous tab the magnesium/zinc alloy work together to slowly dissolve into you water supply as it corrodes. The small amount of zinc contained in neutralizes the odor by transforming the hydrogen sulfide (H2S) to Zinc Sulfate. Zinc Sulfate is a natural mineral that in small amounts can help with normal body functions.

Aluminum VS Magnesium

How Aluminum Breaks Down

How Aluminum Breaks Down

The illustration on the right side here demonstrate how aluminum pieces gather and create a sludgy layer of debris at the bottom of your water heater tank. The red circles with A's inside them represent the pieces of aluminum as they break down. Over time, especially after multiple aluminum rods have ran their complete life cycle, the sludge at the bottom of the tank can damage the porcelain interior of your tank. In severe cases the aluminum sludge can even begin to contaminate your water supply.

Aluminum consumption is believed to be to be linked to Alzheimer disease. It can also lead to other degenerative memory disorders. It can cause damage to your bones structure because aluminum can disrupt the calcium allocation in your bones. Aluminum in general is not meant for consumption. It can also cause damage to vital organs if large enough amounts are consumed over a long enough period. If you do have a condition where using an aluminum rod is your best option please ensure that you are flushing your tank at least annually to eliminate any unhealthy build up. Also always run cold water through your pipes after using hot water to ensure all aluminum residues are free from water you plan on drinking. Even after hot water has cooled down it could still contain small traces of aluminum if the conditions are right. Never drink what comes from your hot water supply when using a water heater that has an aluminum anode rod.

How Magnesium Breaks Down

How Magnesium Breaks Down

The illustrations on the right side here demonstrate how Magnesium dissolves rather than create a sludgy layer of debris at the bottom of your water heater tank. Magnesium is a bio-degradable material. Rather than fall apart and clump at the bottom of your tank Magnesium dissolves and becomes a part of your water as it breaks down. In return, your hot water is enriched with Magnesium. Every time you bath or consume hot water you are absorbing the magnesium in the hot water.

Unlink Aluminum; Magnesium is actually good for your health and your environment. Magnesium is already contained within natural water so pollution is not an issue. Magnesium is also known to be a key element in DNA replication. Among the many health advantages of Magnesium here are a few that should appeal to everyone:

· Malfunction of the Blood-Brain Barrier

· Stomach &Ulcers

· Mental Defects in Infants

· Gastrointestinal Disease

· Learning Disorders in Children

· Parkinson's Disease

· Skin Problems

· Hyperactivity

· Constipation

· Lack of Energy

· Liver Disease

· Nausea

· Headaches

Easy Maintenance with the Drainage Kit

Easy Maintenance with the Drainage Kit

If you use an aluminum rod it is critical that you flush your water heater tank at least annually to minimized aluminum particulars in your water heater tank. Over the years many customers have asked what the easiest way to flush your tank is. We have recently released our drainage valve kit to help potential customers simplify this process. The Drainage kit comes with a Full Port Brass Valve that provides a 3/4 inch connection compatible with your average garden hose. This provides a method for easily draining your water heater annually to reduce sediment buildup. This valve also provides an opening large enough for a long narrow object to breakup any hardened material that has collected at the bottom of the tank. The Full Port Valve comes with a water tight cap so that you can easily secure the connection when not in use.

How to Replace an Anode Rod

How to Replace an Anode Rod Part 1

How to Replace the Anode Rod

CAUTION: Draining your water heater for this procedure may put you at risk of being scalded by hot water. Please be careful when working on your water heater.

Turn the power OFF to the water heater at the circuit breaker (electric heater) or main gas line (gas heater).

Fasten a length of garden hose to the drain valve at the bottom of the heater. Put the other end of the garden hose in the nearest floor drain or snake it outside the home.

Close the shut off valve at the cold water inlet line.

Open the temperature and pressure relief valve at the top of the heater. This will relieve pressure inside the tank. Now open the drain valve and allow about a gallon of the water to drain. You will probably notice some small white particles (called scale or sediment) during the early stages of the flow.

How to Replace an Anode Rod Part 2

How to Replace the Anode Rod

CAUTION: THE WATER WILL BE HOT...........BE SURE NO ONE IS NEAR THE DRAIN HOSE OR THEY COULD BE SCALDED.

After about a gallon of water, close the drain valve and remove the hose. Leave the temperature and pressure relief valve at the top of the heater open for the time being.

Remove the old anode rod with a 1 and 1/16 inch six-sided wrench or socket. Do NOT use a 12-point wrench or socket or you will strip the head of the anode. Get at least a 24-inch cheater bar. I keep a piece of 3/4 inch black iron pipe in the garage just for this purpose. Place the cheater pipe over the socket handle. Have someone hold the water heater while you slowly break the seal. Once broken, the anode removes quite easily.

Replace with a new anode rod. It is a 3/4-inch National Pipe Thread (NPT) part. You may find one at any plumbing house or home store. Use pipe sealer or Teflon tape to seal the threads. Snug it down tight. Remember the water heater builds up 150 PSI of pressure inside the tank.

Open a hot water faucet somewhere in the home. Open the shut off valve at the cold water inlet line. You will hear the heater start to fill.

When you have a steady stream of water from the temperature and pressure valve tube, close the valve; when you have a steady stream of water from the hot water faucet, turn the faucet off.

Turn the power ON to the water heater at the circuit breaker (electric heater) or main gas line (gas heater; relight pilot if required). Allow the water heater to recover. Check the anode rod one more time to make sure it is tight and there are no leaks.

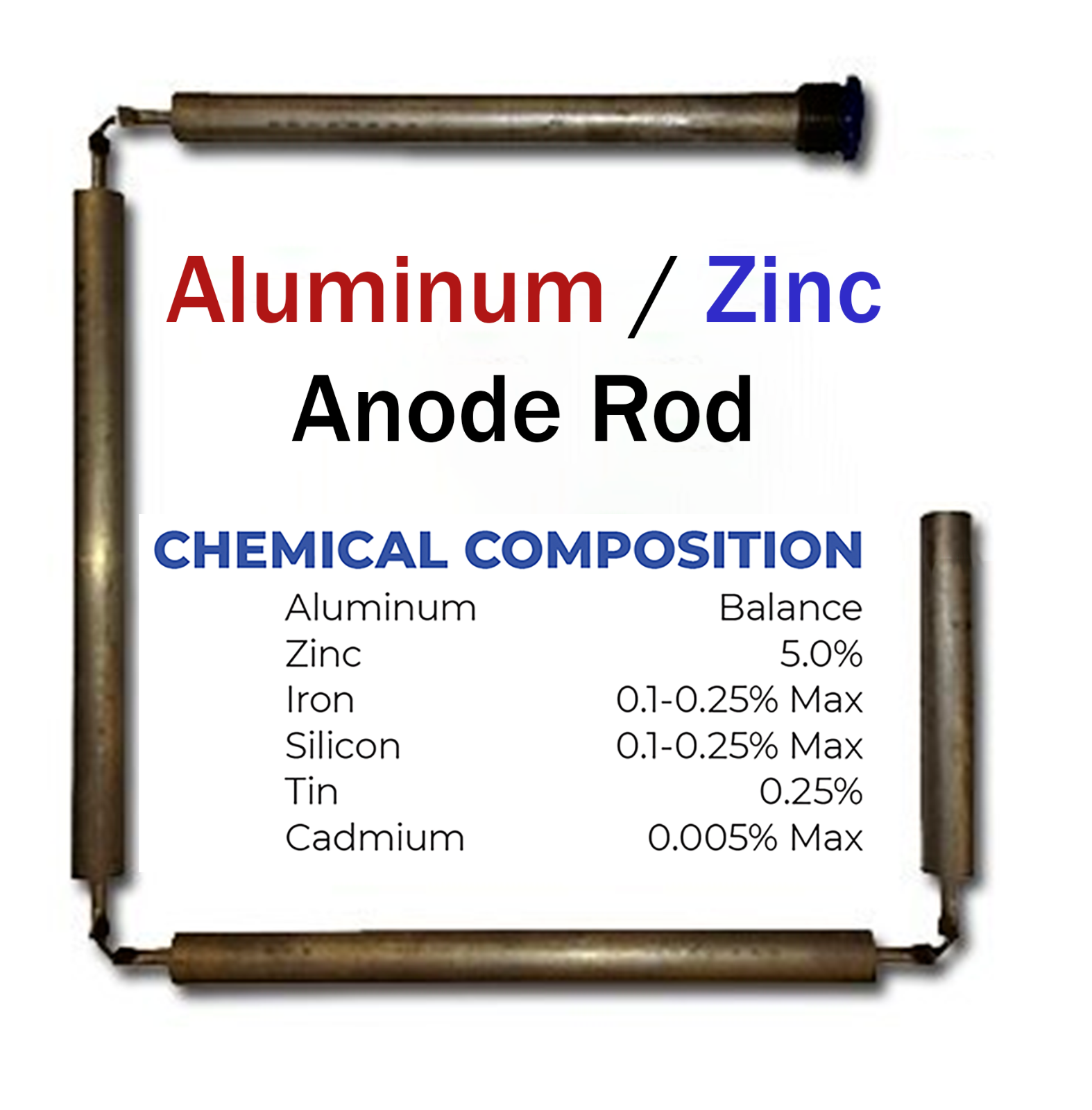

Blue Lightning Aluminum / Zinc Flexible Anode Rod

Residential with Hex Head

Product ID:

79118

If you have smelly hot water this rod is for you!! The zinc in this anode rod is designed to combat odor that comes from your hot water tank. Often times when well water is used H2S builds up causing a rotten egg smell to come from your hot water. Zinc counteracts this natural process and eliminates the unwanted odor.

This is the Hex Plug model of the Blue Lightning Aluminum Flexible Anode Rod. This model has a length of 42 inches, a diameter of .75 inches, and 3/4-14 NPT thread size (This sizing should be standard for the bulk of residential water heaters). The rod is broken down into four separate segments. Each segment is Aluminum on a steal rod core. The segments are attached via copper or stainless steel couplers and 301 stainless steel braided wire. All of our Anode Rods are lead free!

In most cases we recommend our Magnesium version of the Blue Lightning Rod but sometimes magnesium can have a hard time standing up to harsher water conditions. Aluminum is best to use when you know your water is hard and you have experienced rapid deterioration of your previous anode rod. Aluminum rods are also best to use if you use a water softener.

The Blue Lightning Aluminum Anode Rod should be checked on an annual basis and in most cases replaced every other year depending on the rate of deterioration.

►

What is an Anode Rod - YouTube

Video will open in a new window

[isdntekvideo]

►

Installing a Plug Type Anode Rod - YouTube

Video will open in a new window

[isdntekvideo]

Installing a Nipple Type Anode Rod - YouTube

Video will open in a new window

[isdntekvideo]